The majority of damage to warehouse concrete floor repairs are regarding the joints. The concrete joints are highly susceptible to damage because of the point of impact that hard-wheeled traffic has on them; chipping them away at varying rates. Concrete joint damage can be resolved limiting your exposure to safety concerns, lost or damaged products, or costly forklift maintenance. Read more about our concrete joint repair services here.

The Best Ways to Restore Concrete Joint Damage:

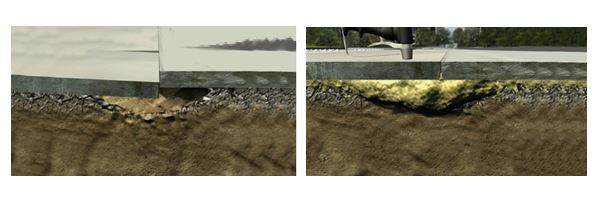

- Prevention with Joint Filler – When warehouses are built, part of the construction plans should include joint filler. Preventing concrete joint damage is the first line of defense. When the small cracks are filled with an epoxy or polyurea, the transition is smooth and significantly reduces the for impact for damage at the joints. However, careful consideration should be taken at the time at which the joint filler is installed. Concrete is continues to shrink and lose moisture for a long time depending on the slabs construction, and the longer you can wait before installing the joint filler the better it will be for it’s success at protecting the joints fully.

- Damage Control As Soon As Possible – At the first sign of concrete joint damage, action should be taken. Small spalls can easily be restored with a variety of different products; however if the spalls become large joint rebuilding may be required. If the joints in the facility aren’t filled, now is the time to do so. Filling the joints during concrete joint repair, will further prevent damage. However, there is a wrong way (we call it a bandaid) to fix damaged concrete joints. Simply squirting divots or spalls with epoxy is a temporary fix and can actually lead to more damage as it may create more points of impact under forklift traffic. There is however, a proper way to rebuild damaged joints. See below for a 6-step process using industrial products for a lasting solution.

- Sub Slab Void Filling – Sometimes joints will fail, crack (especially at the joint intersections), and deteriorate if there are voids beneath the slab making it too weak for heavy loads. When this occurs, sub slab injections of light weight urethane can be installed to fill the voids and make it suitable for traffic once again. Once the sub slab void filling occurs, the surface damage can be restored as mentioned above.

- Joint locking Stabilization Devices – Another option for sub slab voids or rocking slabs are the joint locking stabilization devices. These devices are placed in the areas of concern to put positive pressure on both sides of the slabs holding them together under heavy loads. This final fix for concrete joint damage, can easily be re-tightened periodically if slabs become lose again.

Slab with Joint Saver

Concrete Floor Restoration & Joint Rebuilding

Titus Restoration has been providing turn-key concrete floor restoration projects in warehouses for decades. Where structural or surface repairs are needed, we can help! Titus is equipped to handle any size project, phase around operations, and get the job done efficiently! Contact our experts today for questions on your concrete floor restoration project.