At Titus, we are experienced in utilizing concrete joint filler to optimize the performance of your concrete floor in retail spaces and in industrial warehouses. We use concrete control joint filler and concrete expansion joint filler based on the needs of your space.

Concrete Control Joint Filling

Concrete Expansion Joint Filling

Control Joint Filling

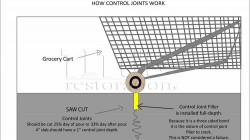

Concrete control joints are intended to be cut the first or second day following placement of the slab at either 25% or 33% percent depth (depending on the day cut). Their purpose is to “control” stress cracking in the slab as the concrete expands and contracts with changes in moisture and temperature. If desired, control joint filler can be installed.

Polyurea joint filler is intended to give the concrete joints protection under weight and traffic. This is a 2-part semi–rigid product that cures quickly, reaches high compressive strength, and forms a 3-sided bond.

- Control Joint with Filler

This type of concrete joint filler can be used in new construction in control joints or in existing concrete floors wear traffic is high and concrete joints need protection. When used in conjunction with polished concrete, joint filler is ground and polished smooth to provide a seamless floor that is not only protected, but easier to clean keeping debris out of the cracks.

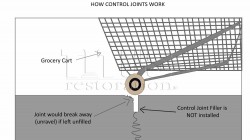

Some control joints are filled with foam, zinc (or other metal) strips, epoxies, or are left unfilled. This type of concrete joint sealant sees the most failures resulting in cracked and broken concrete, as opposed to concrete joint filler we use, as they lack the flexibility to withstand heavy, industrial traffic.

- Control Joints without filler

When varying types of concrete joint fillers fail, concrete floor joint repair is needed. This process differs depending on the environment. All concrete joint repair requires assessment of the load transfer weight, the strength of the concrete, and the hardness of the concrete to determine the appropriate concrete joint repair method.

- Concrete Joint Filling – Before

- Concrete Joint Repair – After

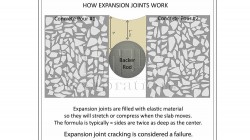

Expansion Joint Filling

The concrete expansion joint is visibly larger than the control joints and they allow for movement of the concrete slab due to vibration, settling, or temperature changes. The most common type of concrete expansion joint filler is caulk. Expansion joint caulk (or expansion joint sealant) is typically installed over backer rod or other foam insert, it forms a bond on 2 sides only.

- Expansion Joint Filler

If the expansion joint filler has cracked or broken away from one side of the joint it is considered a failure. Further, if the concrete joint filler has caused more concrete damage such as crumbling, cracked, or broken concrete at the joint, it is in need of concrete joint repair.

Titus can perform the necessary concrete expansion joint filling for your concrete restoration project to protect the concrete from heavy forklift traffic and load transfer.