Every architect has many options on who to spec for polished concrete floors and the industry has become more standardized, but here are some guidelines to help achieve a proper polished concrete specification for architects.

Read our comprehensive specifications for polished concrete here.

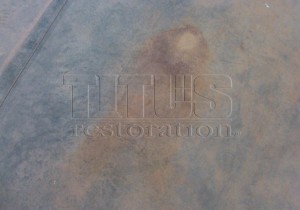

Rust stains in concrete: When specifying polished concrete, did you take into account the protection during construction clause. There are other dangers to look out for when writing polished concrete specifications detailed below.

Great Results Begin with Specifying a Great Concrete Slab

A great looking polished concrete job begins with a great looking concrete slab. To achieve this result, you, the architect, must provide a great specification and demand results. The architectural specification for concrete polishing needs to start with the look that you, the architect, are trying to achieve. Do you want a cream finish, sand exposure, seeded aggregate? Do you know what it will look like when you’re done?

Here are some tips on specifying the concrete slab. This requires proper concrete placement: proper curing, floor flatness (FF numbers), floor level number (FL), proper mix design; proper fiber and fiber weigh per yard of cement; and materials to protect the polished concrete slab from construction damage…before and after concrete polishing. Titus suggests finding a qualified Polishing Subcontractor to help you write the specifications. You must also determine the aggregate exposure you desire in your polished concrete floor and you should understand the risk of each aggregate exposure you consider.

Get an Experienced Polisher Involved at the Polished Concrete Spec Writing Phase

An architect cannot get his polisher involved too soon in the project spec writing. While there are a lot of set rules in concrete polishing, There is a big difference to a polisher between a Methods and Material Spec and a Performance Spec. Sure, there are some general rules to polishing concrete, but everyone who has been on at least more that one job knows no two slabs are alike, thus the big reason to not specify a methods and materials spec.

Protection During Construction is Key for The General Contractor

There will be many trades on the slab prior to the polishing. Because of this, it is important to specify protection in the concrete polishing spec. Oil, rust, and red chalk all leave stains that are nearly impossible to remove with the polishing process without exposing large aggregates. This is going to be the finished floor – nothing is going on top of it – so protection is key. Here are some more tips on protection.

Reality of Polished Concrete

Most of the images on the web show beautifully polished concrete floors – which is acheviable when a proper spec is written and followed, but not always. Have you ever seen a concrete slab without a crack? So, we have created a gallery full of images of “what can happen” to a polished concrete floor that is out of the hands of the polisher, we call it, The Reality of Polished Concrete.

Obtain a Titus Restoration Polished Concrete Specification today, just contact us – we’d be happy to share our experiences with you!